MIL-DTL-21097/16F

NOTES:

1. Dimensions are in inches.

2. Unless otherwise specified, tolerance is ± .015 (.38 mm) for three place decimals.

3. Metric equivalents are given for information only.

4. For field repair use contact specified on slash sheet MIL-DTL-21097/17.

FIGURE 1. Crimp type contact - Continued.

REQUIREMENTS

Dimensions and configuration: See figure 1 and table I.

Use: With connectors conforming to MIL-DTL-21907/13.

Individual contact engagement and separation forces: Dimensions of the gage shall be in accordance with MIL-

DTL-21097/19.

Finish: Gold plating in accordance with ASTM B488, type II, code C, class 1.27, over nickel plating in accordance

with SAE-AMS- QQ-N-290, class 2, 30 to 150 microinches.

Contacts shall be crimped in accordance with manufacturer's recommended tooling.

Part or Identifying Number (PIN): M21097/16-(dash number from table I).

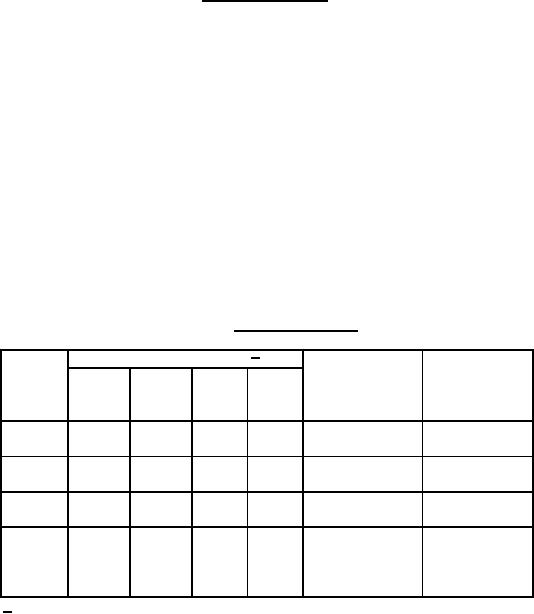

TABLE I. Contact crimp type.

Dimensions (inches) 1/

Insulation

D

C

B

A

±0.015 ±0.015 ±0.15 ±0.15

Wire size

diameter

Dash

number

(0.38) (0.38) (0.38

(0.38)

01

.100

.090

.075

.060

#28 - #24 AWG

.030 - .060

(2.54)

(2.29) (1.91) (1.52)

(0.76 1.52)

02

.125

.125

.075

.060

#28 - #24 AWG

.050 - .078

(3.18)

(3.18) (1.91) (1.52)

(1.27 1.98)

03

.120

.111

.090

.080

#24 - #20 AWG

.040 - .080

(3.05)

(2.82) (2.29) (2.03)

(1.02 2.03)

04

.165

.130

.120

.088

2-#22 or 2-#20

2-.045-.072 or

(4.19)

(3.30) (3.05) (2.24)

or

(1.14-1.83)

1-#18 AWG

1-.075-.095

(1.91-2.41)

1/ Millimeters are in parentheses.

Changes from previous issue. Marginal notations are not used in this revision to identify changes

with respect to the previous issue due to the extent of the changes.

2

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business