MIL-DTL-642/3B

Inches

mm

Inches

mm

Inches

mm Inches

mm Inches

mm

.002

0.05

.020

0.51

.250

6.35 .4375

11.11 .750

19.05

.003

0.08

.093

2.36

.296

7.52

.448

11.38 .776

19.71

.005

0.13

.175

4.45

.370

9.40

.500

12.70 1.562

39.67

.008

0.20

.187

4.75

.390

9.91

.523

13.28 1.625

41.28

.015

0.38

.218

2.54

.437

11.10 .550

13.97 2.500

63.50

NOTES:

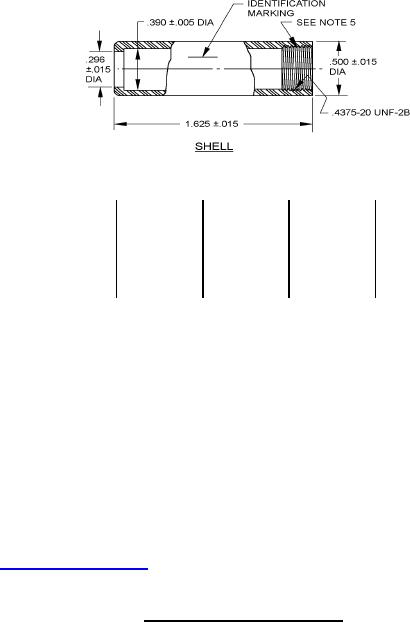

1. Dimensions are in inches.

2. Metric equivalents are given for information only.

3. Unless otherwise specified, tolerance is ±.010 (.25mm).

4. After assembly, the eccentricity between the end of the shank and the tip of the plug shall not exceed

.008 inch (.20mm) total indicator reading (TIR).

5. There shall be a sufficient length of thread on the shell to assure a minimum thread engagement of

four full threads between the shell and the body of the plug after assembled. When the plug shell and

body are assembled, the shell shall not protrude beyond the shoulder of the plug.

6. Details of this assembly shall be in accordance with drawings referenced herein and may be obtained

online from https://cecom.army.mil/ or from US Army Communications-Electronics Command, 6002

Combat Drive, Aberdeen Proving Ground, MD 21005.

FIGURE 1. Dimensions and configuration - Continued.

REQUIREMENTS:

Dimensions and configuration: See figure 1.

Shell shall be plastic in accordance with MIL-DTL-642.

Terminal screws shall be .086-64 UNF-2A in accordance with MIL-DTL-642/12.

One cord clamp in accordance with Signal Corps drawing SC-A-7674 shall be supplied with each plug.

2