MIL-DTL-83538D

4.6.11.2 Electrical engagement-launcher receptacle to buffer plug. Connector halves shall be slowly

mated by normal mating means until first indication of a completed circuit is observed. Means shall be

provided to assure that electrical contact is made between the pin and the spring of the socket contact,

rather than the hood of the socket contact. The mating operation shall be held at this point and the

overall connector length shall be measured from solid reference points on the connector halves. The

mating operation shall then be continued until the connector halves are in the completely mated position.

A second overall length measurement shall then be taken from the same reference points. The

difference of these two measurements shall be not less than that specified in 3.15. Both the outer shield

and inner conductor circuits shall be included in the test of shielded contacts.

4.6.12 Gauge location. Applicable test gauges, conforming to figure 4 shall be installed in three

randomly selected cavities in each connector. With each test gauge fully seated back against its contact

retention device, the axial location of the front end of each gauge shall be measured relative to the

4.6.13 Gauge retention. Applicable test gauges as specified on figure 5 shall be installed in three

randomly selected cavities in each connector. The axial load specified in 4.6.14 shall be applied to

individual test gauges in both directions. The load shall be applied at a rate of approximately 4.45

newtons (1 pound) per second until the specified load has been reached. Gauge displacement shall be

measured with respect to the connector shell after an initial load of 8.9 Newtons (2 pounds) has been

applied to assure that all slack has been taken up (see 3.17).

4.6.14 Contact retention. Unless otherwise specified, contacts shall be tested to procedures I and II

(see 3.18).

4.6.14.1 Procedure I. The contact retention shall be tested as specified in test procedure EIA-364-29.

The following details and exceptions shall apply:

a. Number of samples: The test shall be performed on one size 8 contact, one size 12 contact, two

size 16 contacts and two size 20 contacts. Two size 16 and four size 20 contacts on the AIM-120

side of the buffer adapter shall be tested. The test shall be performed on both receptacles and in

each direction on the buffers.

b. Applied axial load: Preload to 13.6 newtons maximum (3 lbs). Apply load as specified in

c. Special requirements: Where the test sequence required maintenance aging prior to contact

retention, the contacts which were subjected to maintenance aging shall also be selected for

contact retention.

d. Axial direction: The applicable forces shall be applied along the longitudinal axis of individual

contacts in the direction tending to displace the contacts to the rear.

e. Only the contacts to be tested need be installed in the connector.

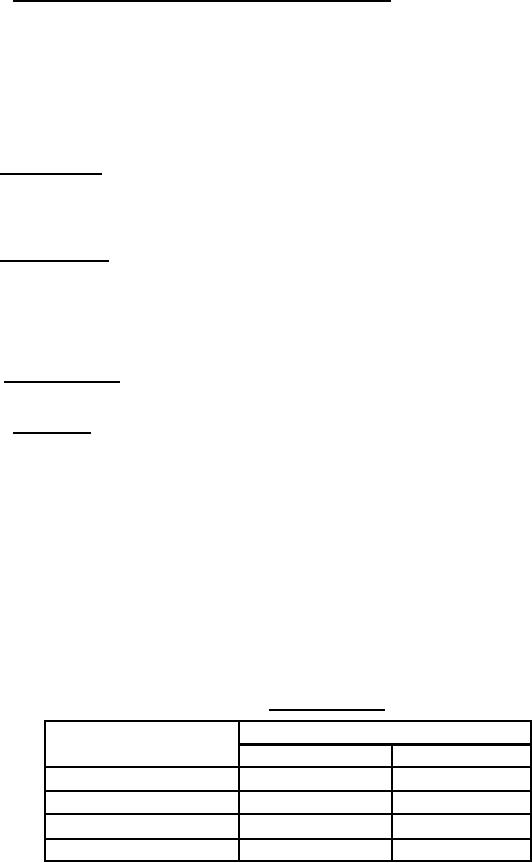

TABLE XII. Contact retention.

Load ±10 percent

Contact

Newtons

Pounds

20

67

15

16

111

25

12 coaxial

111

25

8 twinaxial

111

25

32

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business