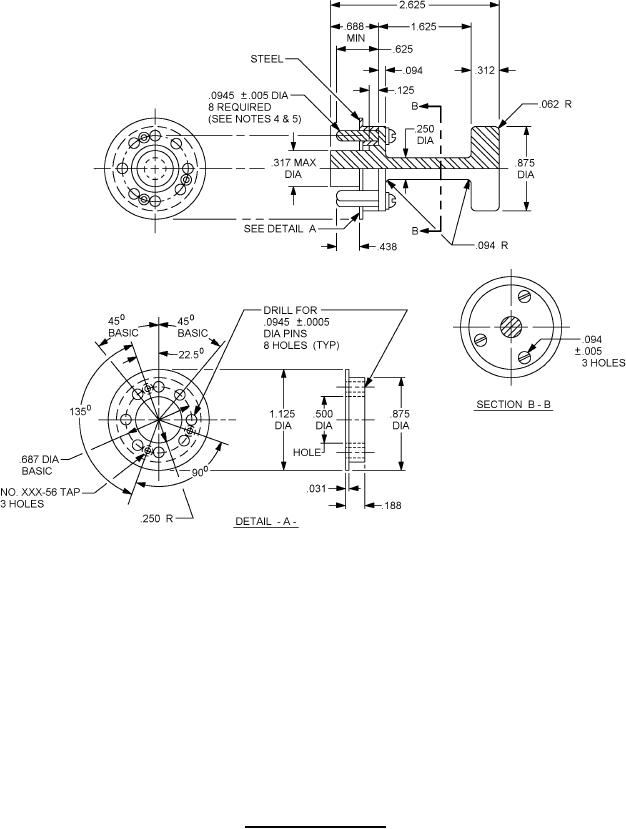

MIL-DTL-12883F

APPENDIX

Inches

mm

.005

0.13

.031

0.79

.062

1.57

.094

2.39

.0945

2.40

.125

3.18

.188

4.78

.250

6.35

.312

7.92

.317

8.05

.438

11.13

.625

15.88

.687

17.45

.688

17.48

.875

22.23

1.125

28.58

1.625

41.28

2.265

57.53

NOTES:

1. Dimensions are in inches.

2. Metric equivalents are given for information only.

3. Unless otherwise specified, tolerances are ±.016 (0.41 mm) for three-places decimals and ±1/2° on

angles.

4. The pins shall be steel, hardened to Rockwell C55-65 and polished to a 4 microinches (0.102)

finish in accordance with ANSI B46.1. Ends of pins shall be hemispherical, and the hemisphere

shall be smoothly blended into the pin cylinder without shoulders or tapering. The end of the pin

may be flat for not more than one-quarter of the pin diameter.

5. All pins shall be affixed to gauge body, or to steel retainer when present, within .001 of true position

at the base and at the extremity of the pins.

6. The body of the gauge shall be aluminum in accordance with SAE AMS-4120, type 2024 - T4.

FIGURE 3. Vibration test gauges.

29

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business