MIL-DTL-28731/23G

REQUIREMENTS

Dimensions and configurations: See figure 1.

Material (adapter): Brass in accordance with ASTM B121, ASTM B36, ASTM B16/B16M and

ASTM B124/B124M.

Plating: Adapter shall be gold plated in accordance with ASTM B488, grade C, class (50 -microinches

minimum) over nickel plating in accordance with SAE-AMS-QQ-N-290, class 2, 50 to 150 microinches.

Crimp diameter: .125 inch (3.18 mm) maximum.

Adapter crimp tensile strength: 35 pounds, minimum.

Wire crimp tensile strength: During crimp tensile strength testing of wires, only one wire shall be tested for

each barrel and the required value shall be as shown in table I.

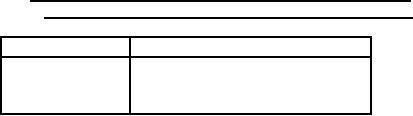

TABLE I. Minimum tensile strength verses wire size (in accordance

with NEMA HP-3 and MIL-DTL-16878/7, or /19 strands).

Wire size (AWG)

Minimum tensile strength (lbs.)

16

35.0

18

25.0

20

20.0

Application: Crimp shall accept wires of the following AWG sizes and combinations: Two AWG 16 wires, two

AWG 18 wires, two AWG 20 wires, one AWG 20 and one AWG 16 and two AWG 20 wires.

Crimping tools (Elco CAGE 12763):

a. Part or Identifying Number (PIN) 18003-024 or equivalent shall be used for 2-16 AWG wires.

b. PIN 18003-025 or equivalent shall be used for:

1. 1-16 and 1-20 AWG wires

2. 2-18 AWG wires

3. 2-20 AWG wires

Contact resistance: Dependent upon wire size. See value specified in table II.

PIN: M28731/23-0001

Note: This unit shall be preassembled by the manufacturer and supplied loose for hand crimping end

installation.

2