MIL-DTL-2036E

3. REQUIREMENTS

3.1 First article. When specified (see 6.2.3), samples shall be subjected to first article inspection in

accordance with 4.3.

3.2 General. Enclosures shall be in accordance with this specification and the requirements of

MIL-STD-108.

3.2.1 Basic requirements (see 4.5). The requirements of MIL-E-917 shall apply for the following:

(a)

Equipment mounting (HI-shock).

(b)

Materials.

(c)

Threaded parts and fastening devices.

(d)

Treatment and processing of metals for corrosion resistance.

Painting (see 6.3).

(e)

(f)

Welding.

3.2.2 Nonmagnetic enclosures (see 4.6.1). When equipment is specified or required to be nonmagnetic,

the material used shall have a permeability of not greater than 2.0. Enclosures for nonmagnetic ships

and craft shall be in accordance with DOD-STD-2143.

3.2.3 Eddy current magnetism (see 4.6.1). Eddy current magnetism requirements apply to nonmagnetic

ships and craft only and shall be in accordance with DOD-STD-2143 (see 6.3).

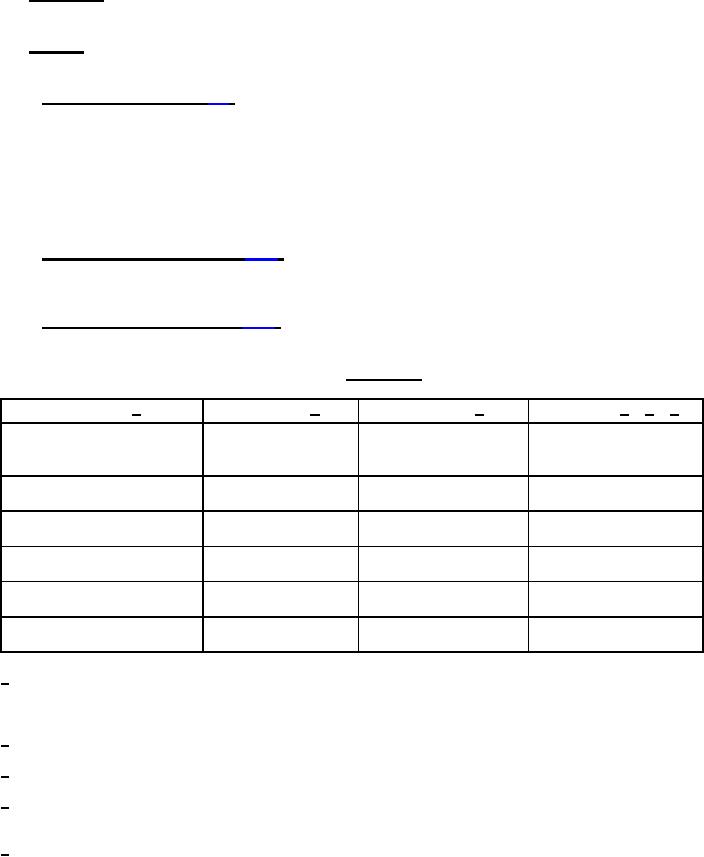

TABLE I. Face areas.

Column 1, 1/

Column 2, 3/

Column 3, 4/

Column 4, 2/, 4/, 5/

Conductivity relative

Thickness of

Cross sectional

Maximum allowable

2

to copper

material inches

area in

face area for face

2

of enclosure ft

Greater than 10 percent

0.25 to 2

10 to 48

5

2

2

(6.35 to 50.8 mm)

(64.5 to 309.7cm )

(.465 m )

Greater than 10 percent

Less than 0.25

Less than 10

12

2

2

(6.35 mm)

(64.5cm )

(1.115 m )

0.29 to 10 percent

Less than 0.25

Less than 24

30

2

2

(154.8cm )

(2.787 m )

(6.35 mm)

Less than 10 percent

0.25 to 1

24 to 28

20

2

2

(6.35 to 25.4 mm)

(154.8 to 180.6cm )

(1.858 m )

Less than 0.5 percent

Any

Less than 24

No restrictions

2

(154.8cm )

1/

Percentage of conductivity (column 1) refers to the electrical conductivity of the material relative to

copper which is rated at 100 percent. Common materials having conductivity greater than 10 percent

of that of copper include aluminum, brass, and bronze. Those having less than 10 percent include

steel (all types) and nickel-copper-aluminum.

2/

(Column 4). The face of the enclosure is that side which has the largest electrically continuous

conducting area.

3/

From the thickness of the material (column 2), determine the maximum allowable area for the face of

the enclosure (column 4).

4/

Obtain the cross sectional area of the material (column 3) by taking the product of the thickness of the

material and the dimension of the side perpendicular to the face of the enclosure. From the cross-

section of the material determine the maximum allowable area for the face of the enclosure (column 4).

5/

Compliance with the less restrictive of the parameters, thickness or cross-section, is satisfactory for

determining the maximum allowable face area of the enclosure.

4

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business