MIL-DTL-28748D

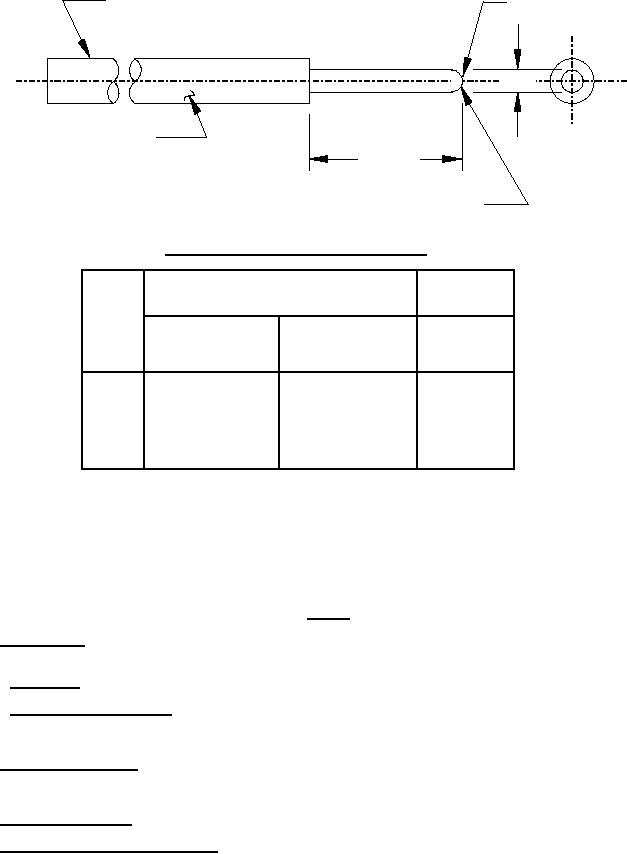

HANDLE SHOWN TYPICAL

B

RECOMMENDED LENGTH 1.0000

MINIMUM DIAMETER TWICE "A" MAX

A

STAMP GAUGE WITH

M28748-# OR MS 3197-#

.500 MIN

RADII SHALL BE SMOOTHLY

BLENDED INTO PIN DIAMETER

Test pins for measuring contact separating forces.

Contact

A

B

size

(mm)

and

dash

Minimum diameter

Maximum diameter

Max

number

+.0001 (0.003)

+.0000

flat

-.0000

-.0001 (0.003)

(mm)

16X1

0.0615 (1.56)

.015 (0.38)

16Y1

---

.015 (0.38)

0.0635 (1.61)

20X1

0.0390 (0.99)

.007 (0.18)

20Y1

---

0.0410 (1.04)

.007 (0.18)

22X1

0.0295 (0.75)

.007 (0.18)

22Y1

0.0305 (0.77)

---

.007 (0.18)

NOTES:

1. Dimensions are in inches.

2. Metric equivalents are given for general information only.

3. Material: Gauge pin for contact sizes 22 and 20, tool steel or tungsten carbide, and for contact size 16, tungsten carbide.

4. Finish: 6 to 10 microinches root mean square determined in accordance with ASME B46.1.

5. No plating.

6. These gauges are intended for use with electric connector socket contacts referenced in this document and in MIL-C-39029.

FIGURE 7. Test pin.

4.7.19 Finish thickness. Finish thickness of the plating and strikes shall be determined by any method which will give results

within ±.010 percent of the true thickness.

4.7.19.1 Overall finish. Plating thickness shall be measured on the external surfaces of the contact body.

4.7.19.2 Localized finish (see 3.3.5.2.2). Finished thickness shall be .00005 inch (0.00127 mm) minimum thickness of deposited

gold. Measurements shall be made at point B or C (see figure 1) as applicable. However, the plating on non-significant surfaces,

nonfunctional surfaces shall be sufficient thickness to ensure plating continuity and uniform appearance.

4.7.20 Industrial gas (see 3.5.17). Unmated contacts shall be placed on a noncorrosive rack in a closed plastic or glass chamber

(volume 2 cubic feet maximum) which contains a 10 percent solution of sulphurated potash NF in distilled water. Contacts shall not

be immersed in the solution but shall be exposed to the sulfide vapor for 100 hours.

4.7.21 Solderability (see 3.5.18). Solder type contacts shall be tested in accordance with method 208 of MIL-STD-202.

4.7.22 Resistance to soldering heat (see 3.5.19). All connectors with solder terminations shall be tested in accordance with EIA-

364-56. The connectors shall be tested in accordance with procedure 1, unless otherwise specified (see 3.1).

25

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business