MIL-DTL-2036E

in respect to the vertical axis. Enclosures designed for optional mounting in more than one orientation

may need to be equipped with more than one drain hole; however, the lowermost hole shall effectively

drain the entire enclosure in whatever optional orientation the enclosure is mounted. The lowermost drain

plug shall be directly accessible with adequate space for wrenching when the equipment is installed in its

operating environment aboard ship; that is, access space shall be provided that will enable a man using

only his hands and an 8-inch adjustable end wrench to remove and replace the effective drain plug in

whatever optional orientation the equipment is installed.

3.2.15 Prevention of leakage along shafts of spraytight and watertight rotating equipment. Except where

integral face-mounted equipment forms a part of the complete assembled equipment enclosure and

eliminates shaft exposure, a means shall be provided, as applicable (see 3.2.15.1 or 3.2.15.2), to prevent

water leakage along the shaft where it penetrates the enclosure.

3.2.15.1 Spraytight. Either of the following leakage preventative methods shall be used to minimize shaft

leakage of rotating equipment:

(a)

A combination of shaft slinger and close clearances between the shaft and housing. The slinger

shall be located immediately outside the housing. The external diameter of the slinger shall be

not less than 1.5 times the shaft diameter and the axial clearance between the end shield and

slinger shall not exceed 0.030 inch (.0762mm). The slinger shall be attached to the shaft using a

set screw or screws. A filler compound may be used to prevent leakage of water through the fit

between the slinger and shaft. The close clearance between the housing and shaft shall be in

accordance with table II. To break up the capillary path of leakage flow through the clearance

between the shaft and the housing at least one peripheral (radial in depth) groove shall be cut in

the housing. The slinger shall be provided with a guard, except that if the slinger end shield or

the coupled equipment design is such as to preclude personal injury, the guard may be omitted.

If the slinger is exposed, omission of the guard shall require the approval of the contracting

activity. Slinger guards, where used, shall permit the expulsion of water.

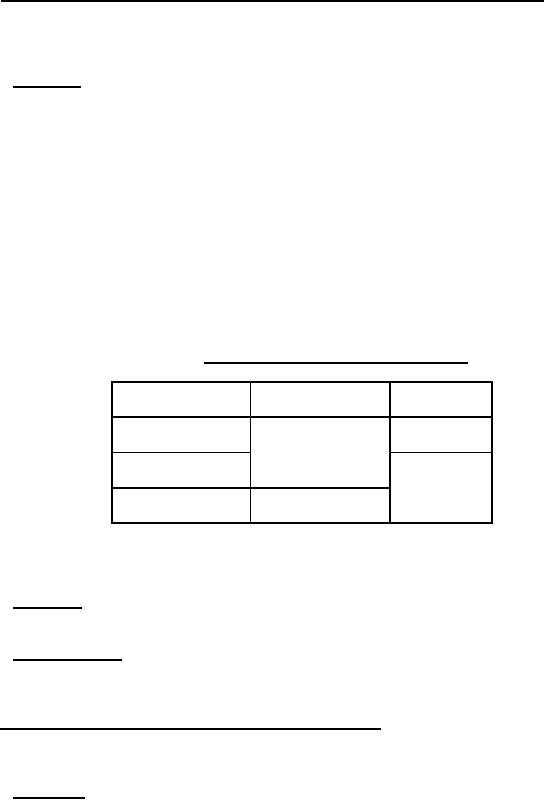

TABLE II. Shaft clearance for spraytight machines.

Shaft diameter

Radial clearance

Axial length

inches

maximum

of clearance

Less than 1

.375 inch

7 mils per inch

(2.54mm)

(9.525mm)

of shaft diameter

(.178mm)

1 to 4

(2.54 to 101.6mm)

.5 inch

(12.7mm)

Over 4

As approved by

(101.6mm)

contracting activity

(b)

A rubbing seal between the shaft and housing. If a rubbing seal is used, the closure shall be

watertight.

3.2.15.2 Watertight. A rubbing seal between the shaft and housing shall be used except where integral

face mounted equipment forms a complete watertight assembly.

3.2.15.3 Totally enclosed. When specified in the contract or order, or the individual equipment

specification (see 6.4), the enclosure shall be such that it can be converted to watertight (see 3.2.15.2) by

the addition of gaskets.

3.2.16 Totally enclosed, water-air-cooled motors and generators. Totally enclosed, water-air-cooled

motors and generators shall be provided with an air cooler of double tube construction to insure against

water leakage into the windings of the machine.

3.2.16.1 Air coolers. Unless otherwise specified (see 6.2.1), air coolers shall conform to class 1, 2, or 3

of MIL-C-19836 as required by the individual equipment specification or as specified (see 6.4).

9

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business