MIL-DTL-24308G

4.5.24 Solderability (see 3.5.23). Solderability, nonremovable contact terminations except wrappost, IDC, and

crimp, shall be tested in accordance with method 208 of MIL-STD-202 (type R or RMA flux may be used). Solder cup

terminations shall be tested in the following manner:

a.

Test samples shall not be cleaned prior to soldering.

b.

Test sample connectors shall have the solder cups dipped in, or brushed with, flux type RMA just prior to the

application of solder.

c.

A pencil type soldering iron shall be used, with temperature regulated to 360°C ±10°C to heat the test

solder cups.

d.

After heating the test solder cups to a solder melt temperature, 63/37 tin-lead type solder shall be applied to

fill the solder cup to a capacity which will result in solder wetting the entire cup surface and forming a solder

fill meniscus across the open portion of the solder cup.

e.

The finished solder fill shall be smooth and slightly concave with clear wetting and adhesion to all internal

surfaces of the solder cup. Inspection shall be aided by a 10X optical aid.

f.

Twenty percent but not less than seven contacts of test specimen shall be tested.

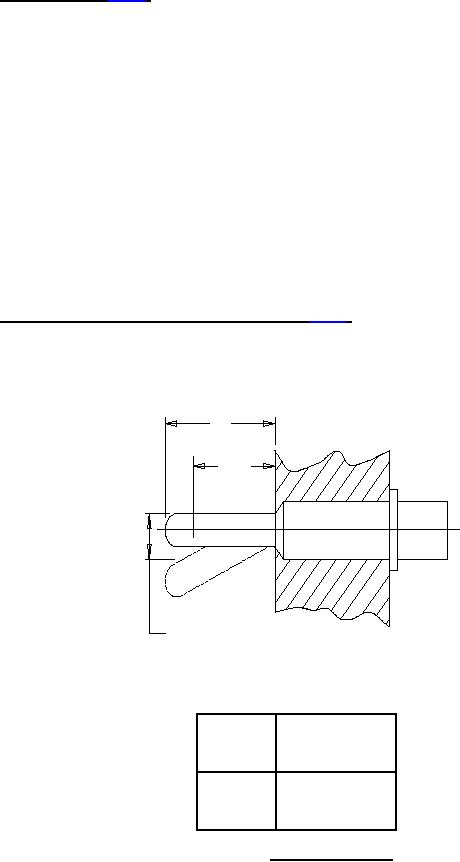

4.5.25 Contact pin strength (nonremovable contacts) (see 3.5.22). Contacts shall be mounted in a suitable fixture

and a gradual load applied to the pin as shown on figure 4. The rate of travel of the testing machine shall not exceed

1 inch per minute, and the load shall be maintained for one minute +15, -0 seconds. The permanent set shall be the

difference between the initial and final position of the load application after load removal.

L

0.8L

MIN

PERMANENT

SET

moment

Mating

(lb-in.)

end

(unless otherwise

size

20

.53

22

.22

23

.16

24

.13

FIGURE 4. Contact pin strength.

22

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business