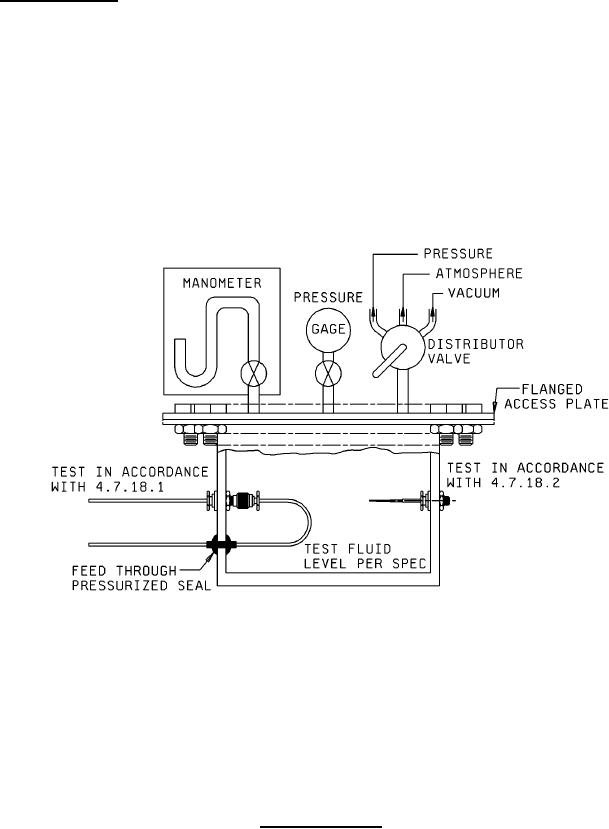

MIL-DTL-25516F

4.7.18.2 Electrical integrity.

a. The connectors shall be removed from the test box, examined for damage, and remounted

approximately as shown on the left side of figure 4 so that the connector receptacle is toward the

inside of the test vessel. Both ends of the electrical wire shall terminate outside the test box.

Water, containing 5 percent salt solution, shall be poured inside the box to a fluid level at least 1

inch below the connectors.

b. A vacuum of 27 inches of mercury shall be applied to the test box for 5 minutes and then relieved.

The box shall be placed in an ambient temperature of 71°C for 1 hour and then reduced to -1°C for

1 hour. Insulation resistance shall be checked at 500 volts dc, using the ends of the outside lead

wire and the body of the connector as terminals. The insulation resistance shall not read less than

200 megohms. This cycle shall be repeated for a total of 10 minutes.

FIGURE 4. Sealed test vessel.

24

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business