MIL-DTL-25516F

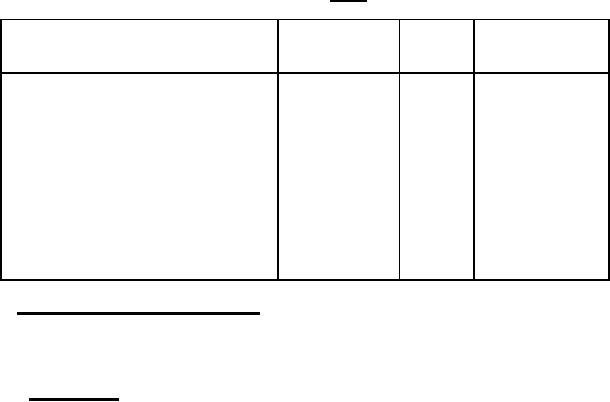

TABLE XI. Fuels.

Temp °F

Fluids

Specification

Immersion time

(hours)

Aviation gasoline

ASTM D910

160

168

Aviation fuel (grade JP-4)

MIL-DTL-5624

160

168

Oil, lubricating, jet engine

MIL-PRF-6081

160

20

(grade 1010, petroleum base)

Lubricating oil, aircraft

MIL-PRF-7808

160

20

Salt water (95 percent water, 5 percent

chloride)

160

20

Diesel, fuel oil

A-A-52557

160

168

Hydrocarbon fluid

ASTM D471

160

168

Aviation hydraulic fluid, petroleum base

MIL-PRF-5606

160

20

4.7.18 Altitude humidity cycling (see 3.6.17). Connectors shall be mounted on a sealed test vessel and

subjected to alternate vacuum-pressure environment in the presence of test fluid and water vapor at both

high and low temperatures to determine leak integrity and the effects on electrical characteristics.

Figure 4 shows the recommended test vessel.

4.7.18.1 Leak integrity.

a. Hermetically sealed and pressurized connectors shall be installed approximately as shown on the

right side of the pressure-tight vessel as shown on figure 4.

b. The test box shall be filled with test fluid, in accordance with type III of ASTM D471, to a level of at

least 4 inches above the connectors.

c. With the fluid in the test box at room temperature, 6 pounds per square inch pressure (lb/in2) shall

be applied to the box and held for 1 hour while checking for leaks.

d. With the test box at room temperature, pressure shall be slowly increased to 20 lb/in2 and then

relieved. This cycle shall be repeated for a total of 10 times. On the tenth cycle, the pressure

shall be held at 20 lb/in2. A check shall be made for signs of leakage and pressure shall be

relieved.

e. The temperature of the test box shall be decreased to 54°C and pressure of 6 lb/in2 shall be

applied and held for 1 hour while checking for leaks. The temperature shall be held at 54°C and

the pressure slowly increased to 20 lb/in2 and then relieved. This cycle shall be repeated for a

total of 10 times. On the tenth cycle, the pressure shall be held at 20 lb/in2. A check shall be

made for leakage. Pressure shall be relieved.

f. The temperature of the test box shall be allowed to return to room temperature and, with pressure

relieved, the wire in the connector shall be pulled from the inside of the test box with a force of 5

± .5 pounds. (For this test, a mechanical device may be rigged to pull the cable or contact from

the inside without removing the cover.). With the test box still at room temperature, the box shall

be pressurized at 6 lb/in2 pressure and a check made for leaks. The pressure shall be

increased to 20 lb/in2 and a check made for leaks. Upon completion of these tests, the pressure

shall be relieved.

23

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business