MIL-DTL-83505B

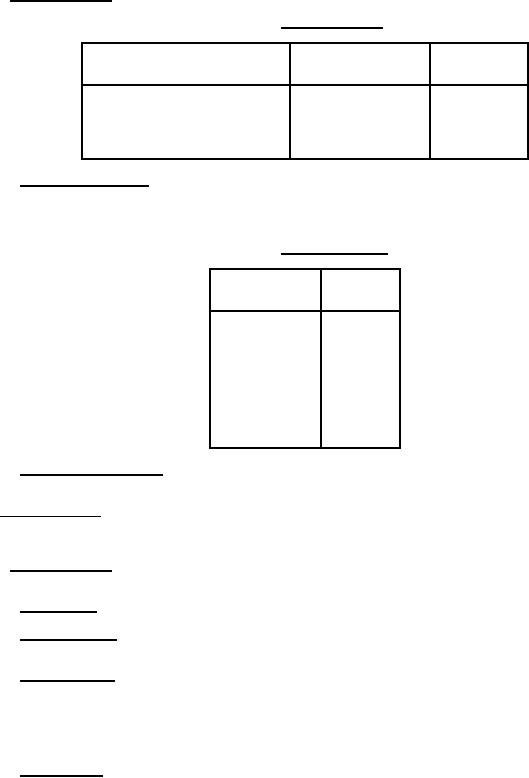

4.5.1.2 Group A inspection. Group A inspection shall consist of the inspections specified in table III, on the same set of sample

units in the order shown.

TABLE III. Group A inspection.

Method

Inspection

Requirement

paragraph

paragraph

3.1, 3.3, 3.4,

4.6.2

Visual and mechanical inspection

3.6, and 3.7

3.5.1

4.6.3

Insertion force

3.5.2

4.6.4

Withdrawal force

4.5.1.2.1 Sampling plan (group A). Table III tests shall be performed on a production lot basis. Samples shall be selected in

accordance with table IV. If one or more defects are found, the lot shall be screened for that particular defect and defects removed.

A new sample of parts shall be selected in accordance with table IV and all group A tests again performed. If one or more defects

are found in the second sample, the lot shall be rejected and shall not be supplied to this specification.

TABLE IV. Lot and sample size.

Lot size

Sample

size

1 to 50

5

51 to 90

7

91 to 150

11

13

151 to 280

16

281 to 500

19

501 to 1200

23

1201 to 3200

29

3201 to 10000

35

10001 to .....

4.5.1.2.2 Disposition of sample units. Sample units which have passed all the group A inspections may be delivered on the

contract if the lot is accepted and the sample units are still within the specification tolerances.

4.5.2 Periodic inspection. Periodic inspection shall consist of group B. Except where the results of these inspections show

noncompliance with the applicable requirements (see 4.5.2.1.2), delivery of products which have passed group A inspection shall not

be delayed pending the results of these periodic inspections.

4.5.2.1 Group B inspection. Group B inspection shall consist of the tests specified in table II, in the order shown. Group B

inspection shall be made on sample units selected from inspection lots, which have passed the group A inspection.

4.5.2.1.1 Sampling plan.

4.5.2.1.2 Single submission. Eight (8 ) sample sockets (type I through IV) or 4 (type VI) sockets from those covered by a single

specification sheet shall be selected at random from items produced every 36 months.

4.5.2.1.3 Inspection routine. The sample shall be subjected to the inspections specified in table I, in the order shown. All sample

units shall be subjected to the inspections of group I. The samples shall be divided as follows and subjected to the inspections for

their particular group.

a. 2 groups of 2 units for type I and VI sockets.

b. 4 groups of 2 units for type II through V sockets.

4.5.2.1.4 Noncompliance. If a sample fails to pass group B inspection, the contractor shall take corrective action on the materials

or processes, or both, as warranted, and on all units of product which can be corrected and which were manufactured under

essentially the same conditions, with essentially the same materials, processes, etc., and which are considered subject to the same

failure. Acceptance of the product shall be discontinued until corrective action, acceptable to the Government, has been taken. After

the corrective action has been taken, group B inspection shall be repeated on additional sample units (all inspection, or the

inspection, which the original sample failed, at the option of the Government). Group A inspections may be reinstituted; however,

final acceptance shall be withheld until the group B reinspection has shown that the corrective action was successful. In the event of

failure after reinspection, information concerning the failure and corrective action shall be made available to the cognizant inspection

activity and to the qualifying activity.

9

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business